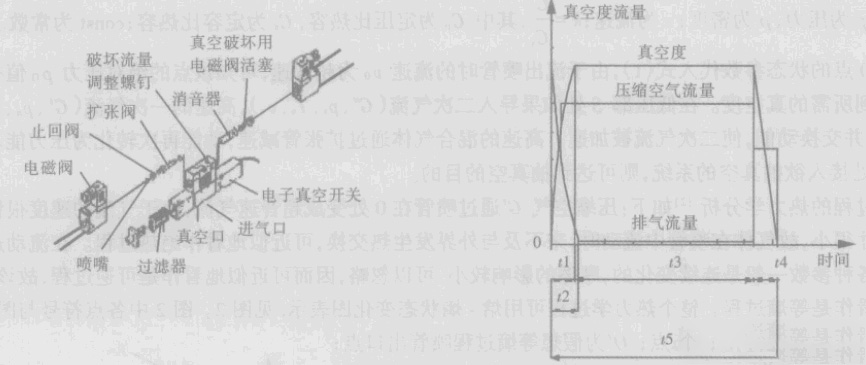

工程上,为了与各种各样的工作要求相适应,通过改变喷嘴、扩张管的尺寸、形状及组合方法,使真空发生器的到达真空度、排气量、压缩空气流量有差异。而在本体上组合控制系统、防尘系统、消音系统中诸如电磁阀、真空开关、过滤器、消音器等,它会使之性能更趋完善。图3 为日本(株)妙德会社CDE 型真空发生器结构示意图。

图3 VCD型真空发生器结构示意图 图4真空吸着过程示意图

真空发生器在电子、钢铁、化工、建筑、食品等行业应用很广,主要在自动机械中起如下作用:

真空吸着搬运。将真空发生器与真空吸盘组合,利用产生的真空吸附工件,将工件送到所需工位。

真空吸着固定。利用真空吸着固定易产生弹性变形的薄工件,进行磨削加工等。

2种用途的吸着过程如图4所示。图中t1为真空发生时间;t2 为工件吸着时间;t3 为搬运时间;t4为真空破坏时间;ts 为搬运周期。装在自动机械上的真空吸盘与工件接触形成密闭空间,然后真空发生器开始工作,压缩空气流量开始急剧上升;同时密闭腔的空气迅速排出,随着密闭腔空气量的减少,排气量迅速下降;密闭腔内真空度很快提高,达到一定真空度后,自动机械运动,带动真空吸盘和工件到达所需工位。

搬运结束时,为了使工件尽快脱离吸盘,故采用向真空吸盘吹入压缩空气的方法来达到快速破坏真空的目的。在从真空发生到真空破坏的吸着运送过程中,真空发生器消耗一定量的压缩空气。对于全自动连续运行的机械,压缩空气消耗量很大。本文即从节能使用真空发生器的角度而进行粗浅的探讨和论述,探讨如何在一定的条件下寻求较佳的节能使用方案。

更所真空吸盘、PIAB真空发生器产品采购,可联系诺典科技!

In engineering, in order to adapt to a variety of work requirements, by changing the size, shape and combination method of nozzle and expansion tube, the vacuum degree, exhaust volume and compressed air flow of vacuum generator are different. The combination of control system, dust-proof system and silencing system, such as solenoid valve, vacuum switch, filter and muffler, will improve its performance. Fig. 3 is the structural diagram of CDE vacuum generator of miaodee society of Japan.

Fig. 3 structure diagram of VCD vacuum generator Fig. 4 vacuum suction process diagram

Vacuum generator is widely used in electronics, steel, chemical industry, construction, food and other industries. It mainly plays the following roles in automatic machinery

Vacuum suction handling. The vacuum generator is combined with the vacuum sucker, and the workpiece is adsorbed by the generated vacuum, and the workpiece is sent to the required station.

Vacuum suction fixation. The thin workpieces which are easy to produce elastic deformation are fixed by vacuum suction for grinding.

The sorption process of the two uses is shown in Figure 4. In the figure, T1 is the vacuum occurrence time; T2 is the workpiece suction time; T3 is the handling time; T4 is the vacuum failure time; ts is the handling cycle. First, the vacuum suction cup installed on the automatic machine contacts with the workpiece to form a closed space, and then the vacuum generator starts to work, and the compressed air flow begins to rise sharply; at the same time, the air in the closed cavity is discharged rapidly, and with the reduction of the air volume in the closed cavity, the exhaust volume decreases rapidly; the vacuum degree in the closed cavity increases quickly, and after reaching a certain vacuum degree, the automatic machine moves to drive the vacuum The suction cup and workpiece arrive at the required position.

At the end of transportation, in order to make the workpiece out of the suction cup as soon as possible, the method of blowing compressed air into the vacuum suction cup is adopted to quickly destroy the vacuum. The vacuum generator consumes a certain amount of compressed air in the process of suction transportation from the occurrence of vacuum to the destruction of vacuum. For fully automatic continuous operation machinery, compressed air consumption is very large. In this paper, from the perspective of energy-saving use of vacuum generator, we discuss how to find the best energy-saving scheme under certain conditions.